When choosing cover materials for neon lights, silicone and PVC are the most common options. The general belief is that silicone “outperforms” PVC in performance and quality. However, the truth is that in the most frequent real-world neon sign application, PVC neon light cover is actually the more suitable and advantageous choice.

This article will answer 3 key questions: Where is the most common application scenario for neon signs? What specific advantages does the PVC neon light cover offer? And what are the primary concerns that professional buyers have about PVC material?

Table Of Contents

1. Silicone vs. PVC: A Quick Performance Comparison

First, we must acknowledge that silicone does outperform PVC in certain areas, such as high and low temperature resistance, long-term outdoor durability, extreme flexibility, and overall environmental friendliness. For a detailed comparison of their performance, there is already a good resource on Silicone vs. PVC: Performance Comparison. Feel free to refer to it for more background.

However, the best performance does not always mean the best fit. For neon signs, the most common usage scenario actually highlight PVC’s unique strengths while minimizing its weaknesses.

2. What is The Primary Use Case For Neon Signs?

The answer is: indoor, dry, room-temperature commercial or retail spaces. This type of space is a very common environmental classification in commerce, logistics, and product storage. Such spaces typically require controlled and stable conditions, making them suitable for storing most goods that are not sensitive to temperature or humidity, and they also serve as primary venues for commercial activities. Here are some specific types and examples of such spaces:

2.1 Retail Spaces

- Shops in Shopping Malls/Centers: Clothing stores, shoe stores, jewelry stores, cosmetics stores, gift shops, bookstores, electronics retail stores (e.g., Apple Store).

- Department Stores: Such as Macy’s, Galeries Lafayette, etc., including their various product sections.

- Specialty Retail Stores: Furniture stores, home goods stores, toy stores, sporting goods stores, eyewear stores, pet supply stores.

- Convenience Stores and Small Supermarkets: 7-Eleven, FamilyMart, as well as small community supermarkets.

- Brand Showrooms and Flagship Stores: Urban showrooms for automotive brands, flagship stores for high-end fashion brands.

2.2 Commercial Office and Service Centers

- Office Buildings: Corporate headquarters, law firms, accounting firms, design studios, technology company offices.

- Banks and Financial Institutions: Branch outlets, securities company offices, insurance company customer centers.

- Service Centers: Telecom service halls, customer service centers, travel agency branches.

- Healthcare Service Points: Dental clinics, eye clinics, medical examination centers, retail areas of pharmacies (non-warehouse areas).

2.3 Leisure and Entertainment Spaces

Cinemas, bowling alleys, billiard halls, arcades, indoor children’s playgrounds, gyms and yoga studios, museums and galleries.

2.4 Commercial Display and Transaction Spaces

- Trade Show Halls and Exhibition Centers: Booths and public passageways during events such as auto shows, wedding expos, and industry exhibitions.

- Model Units and Sales Centers: Indoor model units and sales offices for real estate projects.

- Auction House Galleries: Spaces for displaying artworks, antiques, etc., during preview periods.

2.5 Storage and Back-End Support Spaces

Retail back-end warehouses, sorting and packaging areas in e-commerce fulfillment centers.

3. Three Key Advantages of PVC Neon Light Cover

It is in this scenario, which represents the vast majority of the market, that PVC neon light covers show their strong competitiveness.

3.1 Cost-Effective of PVC Neon Light

This is PVC neon light cover’s most straightforward advantage. For LED neon sign factories and LED neon light traders, controlling costs is essential.

3.2 Vibrant and Saturated Colors with Outstanding Advertising Effectiveness

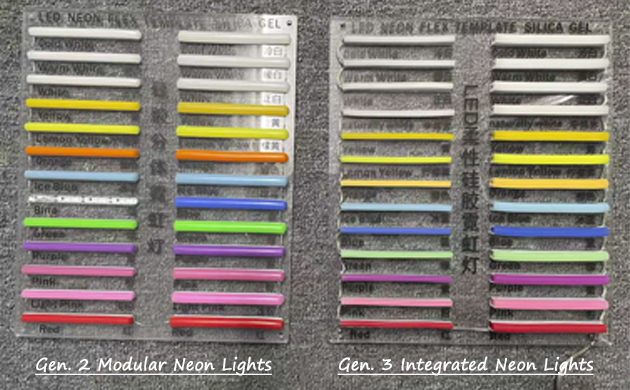

The primary task of an advertising sign is to “catch the eye”. PVC neon light cover material particles exhibit extremely bright and highly saturated colors after processing, delivering strong visual impact and perfectly meeting the advertising industry’s demand for vibrant hues. The visual superiority of PVC over silicone in terms of color vividness stems mainly from its physical properties—such as refractive index and gloss—as well as its superior pigment dispersion capability. Below is a detailed explanation:

3.2.1 High Refractive Index: PVC has a refractive index of approximately 1.54, which enhances its interaction with light. In contrast, silicone has a refractive index of about 1.40, resulting in relatively weaker light reflection. This fundamental physical property is why PVC colors appear more vibrant. Silicone, with its lower refractive index, tends to look softer and is less prone to producing neon-like glare.

3.2.2 High Gloss: As noted in an optical expert article on LinkedIn, PVC has a strong ability to reflect light, contributing to excellent clarity. Silicone, especially solid silicone, often contains fillers (such as silica) that naturally introduce a degree of haze. This inherent “cloudiness” of silicone substrates absorbs some light, diluting the purity of its colors.

3.2.3 Differences in Pigmentation and Molding Processes: According to an industry report from Extreme Molding, PVC offers excellent free-dyeing properties. Pigments can disperse uniformly and at high concentrations within PVC molecular chains, faithfully reproducing the original color of the pigment. In contrast, silicone coloring relies mainly on masterbatches or color pastes. During the high-temperature vulcanization (curing) process of silicone, pigments may undergo slight hue shifts or darkening under sustained heat, ultimately affecting color vibrancy.

Another critical but often overlooked comparison is that, although silicone itself exhibits excellent weather resistance, the colored outer layer of silicone neon signs fades faster under indoor UV exposure (e.g., in shop windows) than that of PVC neon signs. Certain colors, such as red and purple, may show visible fading in silicone neon signs within just 1 week! The reasons are as follows:

3.2.4 Inherent Pigment Instability in Silicone: According to an academic study from the U.S. National Library of Medicine (PMC), while silicone possesses highly stable Si-O chemical bonds that UV radiation cannot easily break, UV light can penetrate silicone material directly and act on the pigment molecules inside, triggering photodegradation. Without the use of expensive high light-fastness pigments, colors can shift dramatically in a short period.

3.2.5 Surface Protection Function of PVC: As indicated by Uni-Bell PVC Association materials, the effect of UV radiation on PVC is largely confined to a very thin surface layer. This slight surface degradation (dechlorination) can sometimes form a protective layer, slowing further light-induced damage to internal pigments.

3.3 Resistance to Environmental Pollutants, Addressing “New Store Risks”

Silicone neon light is prone to yellowing in newly renovated environments, whereas PVC neon light exhibit relatively stable color performance. This is an exceptionally important and practically proven advantage. Neon signs are typically installed when a client’s new store or office has just completed decoration. Newly renovated environments often contain high levels of phenolic compounds, amines (common in paint curing agents), and nitrogen oxides (NOx).

Silicone neon light cover has a gas permeability rate dozens to hundreds of times higher than that of PVC neon light cover, causing it to absorb chemical pollutants from the environment like a “sponge.” These substances react with residual catalysts or antioxidants in the silicone, producing yellow compounds. This high gas permeability is precisely why silicone is susceptible to yellowing in newly renovated environments.

In contrast, PVC neon light cover is a polar polymer with strong intermolecular forces and a highly compact structure. Gaseous pollutants in renovated environments find it difficult to penetrate deep into the molecular chains of PVC. Even if minor surface adhesion occurs, PVC does not undergo deep absorption like silicone, thus avoiding overall visual yellowing.

Choosing PVC neon light for newly renovated environments is equivalent to adding an “insurance policy” for your signage, preventing aesthetic degradation due to renovation pollutants during the critical early stages of operation.

4. Concerns About Environmental Impact and Safety of PVC Neon Light

Experienced buyers and purchasers often worry about 2 issues regarding PVC neon light cover: environmental odor and fire safety. While these problems do exist in low-quality PVC products, high-quality and environmentally friendly PVC can effectively address them.

4.1 Regarding Environmental Impact and Odor of PVC Neon Light Cover:

The strong and unpleasant smell of cheap PVC comes from low-quality raw materials and recycled plastics. Our factory uses high-purity and environmentally friendly new PVC material, which has minimal residual monomers and eliminates odor at the source. Our PVC neon light products are safe, eco-friendly, and meet strict export standards.

4.2 Regarding Fire Safety of PVC Neon Light Cover:

Ordinary soft PVC has an ignition point of around 200°C and can sustain burning for extended periods. However, the PVC material we use in PVC neon light is specially treated with flame retardants, significantly raising its ignition point. This results in 2 key improvements: First, the material is harder to ignite in case of electrical faults. Second, even if it does catch fire, the flame retardants help suppress the chain reaction of combustion, giving it self-extinguishing tendencies and shortening burning time. This greatly reduces the risk of fire spread, offering greater peace of mind.

5. Conclusion

In summary, selecting a cover material for neon lights is about matching the right material to the right scenario:

- If you need exceptional outdoor weather resistance, ultra-long lifespan, or plan to use the sign in extreme conditions, silicone neon light is the better choice.

- However, if your neon sign will be used in the most common setting: a dry, indoor environment, and factors like cost-effectiveness, vibrant colors, and protection against pollutants in newly renovated spaces are important to you, then environmental PVC neon light is not only a good option but also the more practical and smart solution.

We hope this article helps you move beyond the myth that “silicone neon light cover is always better than PVC neon light cover” and allows you to make a choice that best serves your business needs and practical requirements. If you have more insights or specific questions, feel free to leave a comment! Let’s continue the discussion!

6. Call to Action

As a professional manufacturer with 8 years of deep expertise in the neon lighting industry, One Zero LED Lighting Factory is committed to providing a full range of high-quality neon lighting products.

- Equipped with 6 specialized production lines and comprehensive in-house capabilities from R&D to manufacturing, we can flexibly meet the needs of diverse projects.

- Maintain substantial ready-to-ship inventory across our entire advertising neon light series, enabling fast dispatch within 3–7 days for small to medium orders. This ensures efficient support for urgent projects and allows your plans to proceed with confidence.

Let’s work together to illuminate spaces, ideas, and opportunities with professional products and service.

Contact us today to bring your vision to light.

Email Us: sales@onezeroledlighting.com

Call Us (Phone/WhatsAPP/WeChat): +86 18692631217