The “a gap between certification and reality” issue you’re facing is a common and central pain point in LED neon light product certification. This is especially true for products like outdoor LED neon signs, which require high durability.

Simply put, certification tests the one-time performance of a specific sample under controlled conditions. However, in reality, what is truly tested is the long-term stability of mass-produced products in complex environments.

Consequences of Ignoring the Gap Between Certification and Reality

1. The Certification and Reality Gap: A Quality Disaster

Neon signs fail on a large scale during the warranty period, such as water ingress causing rust, or yellowing and cracking of light strips. This leads to high repair costs and damage to brand reputation.

2. The Certification and Reality Gap: Safety Risks

For outdoor electrical products, water ingress may cause short circuits or electric leakage, creating safety hazards.

3. The Certification and Reality Gap: Financial Loss

Low-cost products save money initially. However, you will pay much more later for frequent replacements and maintenance.

Why is There a Gap Between Certification and Reality?

| The Reasons | Laboratory Certification Scenario | Real-world Usage Scenario | Reasons for the Gap |

|---|---|---|---|

1. Test Subject |

The specific sample sent for inspection is usually a single, carefully prepared product that represents the best craftsmanship. | In mass production, there are variations in material batches, production processes, and worker operations for each individual product. | A sample cannot fully represent production consistency. In other words, “what is submitted for inspection is one thing, but the actual mass-produced goods are another.” |

2. Test Conditions |

The testing environment uses idealized and standardized single conditions. For example, IP65 testing involves spraying water at specified angles, pressures, and for set duration. | The real-world environment is complex, variable, and harsh. Factors such as UV exposure, day-night temperature shifts, chemical corrosion, physical stress, and prolonged rainwater immersion all work together. | Individual tests do not simulate the combined effects or long-term aging from environmental factors. For example, PVC material may pass a short-term water spray test but can become brittle due to prolonged UV exposure. |

3. Test Duration |

Short-duration testing. Certification requires passing only one or a few tests. | The real-world exposure lasts for years, or even up to 5 years, constantly testing the product. | Short-term tests cannot reveal how materials degrade over long-term aging. |

4. Test Motivation and Supervision |

Reliance is placed on the impartiality of certification bodies. However, in reality, some low-quality agencies may lower standards, provide false certifications, or even sell certificates for profit. | Reliance is placed on the quality integrity of manufacturers. However, if a manufacturer lacks responsibility and ethics, the main risk is secretly switching to cheaper materials after certification. | Certification relies on process oversight, but this oversight can have gaps. At the same time, some manufacturers may act without integrity. When these two factors combine, the effectiveness of certification is significantly reduced. |

How to Bridge the Gap Between Certification and Reality?

1. Go beyond certification and focus on the entire production system:

Investigate the factory

First, check whether the manufacturer has a sound quality management and inspection system. Also, make sure to verify if their production control process is stable and standardized. This directly affects whether mass-produced products are consistent with the certified sample.

Here at our factory, we focus on producing advertising neon lights and maintain stable, professional manufacturing capabilities. Unlike some factories that offer a wide range of products, accept any order, and have scattered production processes, we specialize in this field. This allows us to keep our production processes consistently standardized and uniform.

Additionally, our workers are all systematically trained, highly experienced, and follow standardized operating procedures strictly. All of this ensures the high stability and consistency of our products.

Examine History

Prioritize suppliers with long-term experience in producing and supplying outdoor lighting. The reason is that practical, hands-on experience is more convincing than certificates alone.

Since 2018, our factory has established stable partnerships with major neon light design manufacturers and wholesalers. We continue to provide them with core support.

The LED outdoor neon signs produced by these manufacturers are now widely installed in shopping malls, bars, restaurants, bubble tea shops, and other venues around the world. These signs effectively help customers attract foot traffic and enhance their brand image.

In terms of brightness and overall quality, these products consistently receive high recognition and positive feedback from the market.

Inquire About Detail

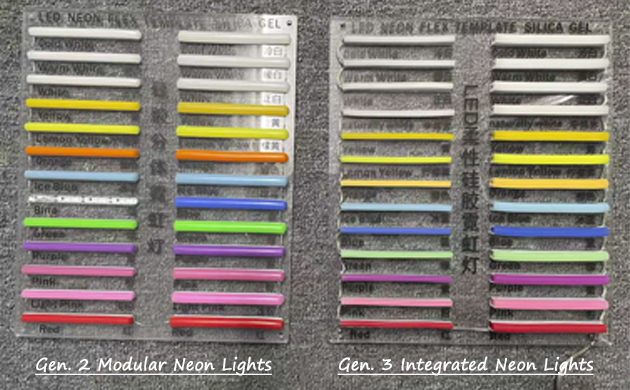

Specifically, inquire about the materials used to handle factors like UV exposure and temperature changes. For example, whether genuine silicone or imitation silicone materials are used. Also, ask about the technical measures in place, such as whether the product is made through integrated molding or uses a sleeve design.

Our advertising neon light series are fully made with integrated molding, providing better sealing, higher light efficiency, and superior waterproof performance.

Assess the focus

Prioritize professional factories that have been focusing on and specializing in the niche field of outdoor LED neon lights for a long time. The extensive experience and craftsmanship gained from long-term production not only help you make quick and correct decisions, but also enable efficient problem-solving for various practical issues in the future.

For example, our factory has been deeply engaged in the LED neon light industry for over 8 years, and we have accumulated solid expertise. Specifically, we have established a complete professional production system with 7 fully automated production lines dedicated to manufacturing high-quality advertising neon lights.

2. Increase Self-verification:

Sample Testing

Random samples are taken from bulk production and sent to a third-party laboratory for key tests, such as aging and low-temperature bending tests.

Small-Batch Trial

Before full project roll-out, a small quantity is installed first and undergoes on-site testing for at least one complete season.

3. Be Cautious of the Low-price Trap:

Be cautious about products with very low prices. This is because true weather-resistant materials, like eco-friendly PVC and silicone, cost more. Also, careful quality control adds to the cost. Therefore, prices that seem too good to be true may mean lower quality.

Conclusion

Certifications are important as entry barriers and reference points, but they do not guarantee quality. For products like outdoor LED neon signs, real assurance comes from high-quality raw materials, careful craftsmanship, honest manufacturers, and overall quality control that goes beyond certification standards.

If you are looking for a manufacturer that offers premium materials, strict process standards, and reliable operations, we invite you to learn more about our factory and contact us.

Call to Action

As a professional manufacturer with 8 years of deep expertise in the neon lighting industry, One Zero LED Lighting Factory is committed to providing a full range of high-quality neon lighting products.

- Equipped with 6 specialized production lines and comprehensive in-house capabilities from R&D to manufacturing, we can flexibly meet the needs of diverse projects.

- Maintain substantial ready-to-ship inventory across our entire advertising neon light series, enabling fast dispatch within 3–7 days for small to medium orders. This ensures efficient support for urgent projects and allows your plans to proceed with confidence.

Let’s work together to illuminate spaces, ideas, and opportunities with professional products and service.

Contact us today to bring your vision to light.

Email Us: sales@onezeroledlighting.com

Call Us (Phone/WhatsAPP/WeChat): +86 18692631217