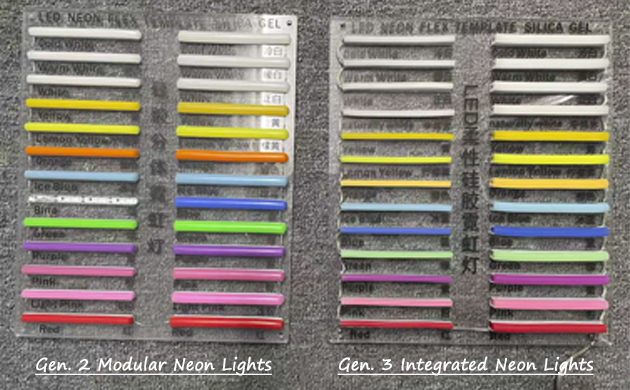

For extruded advertising neon lights, waterproofing neon cut ends is key to ensuring reliable outdoor performance. There are generally two types of advertising neon lights: neon extruded and neon diffuser. The standard cross-section sizes for neon extruded types are 6mm x 12mm and 8mm x 16mm. Below is a step-by-step guide on how to properly waterproof neon cut ends of such one-piece extruded neon lights.

Selection of Neon Light Outer Cover Material

For one-piece extruded neon lights intended for outdoor use, the outer cover must be made of silicone. This material ensures both weather resistance and flexibility.

For more detailed reasons, please refer to the relevant specialized article. What Jacket Material for Outdoor LED Neon Signs is the Optimal?

Selecting the Right Waterproof End Cap to Waterproof Neon Cut Ends

In this article, we will use a 6×12 one-piece extruded advertising neon light as an example. We aim to create an effective waterproof seal for the cut ends, a common need in many commercial neon sign applications. For this purpose, we will use a square silicone waterproof end cap.

If you would like to know about the general types of end caps available for one-piece advertising neon lights, and which type is suitable for which scenario, please refer to the relevant specialized article. What Types of Neon Light End Caps Are Available for One-Piece Neon Lights, and How Do You Choose the Right One for Different Environments?

Waterproofing Steps to Waterproof Neon Cut Ends

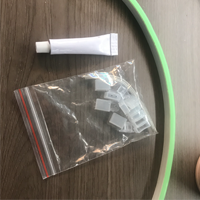

Step 1: Material Preparation For Waterproof Neon Cut Ends

- Square silicone end caps, both with holes and without holes.

- Neutral silicone sealant for end caps.

- A one-piece extruded silicone neon light strip.

- AWG27 transparent purple copper wires.

*Our factory supplies all the above neon lights and accessories. Click here to contact us.*

Step 2: Surface Preparation For Waterproof Neon Cut Ends

First, make sure the cut end of the neon light strip is flat and smooth. Then, clean the surface with alcohol to remove any oil or dust.

Step 3: Sealing Process For Waterproof Neon Cut Ends

- For the neon light tail end without wires:

- Apply neutral waterproof silicone sealant evenly into the closed square end cap. Fill about 1/3 to 1/4 of the cap’s volume.

- Next, insert the tail end of the neon light strip into the cap. Press firmly until the sealant overflows slightly around the strip’s outer cover.

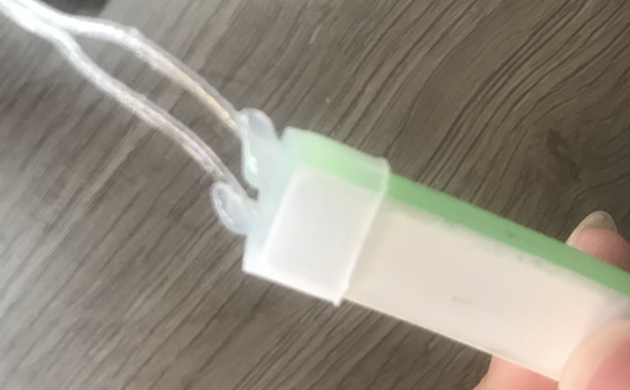

- For the head end with wires:

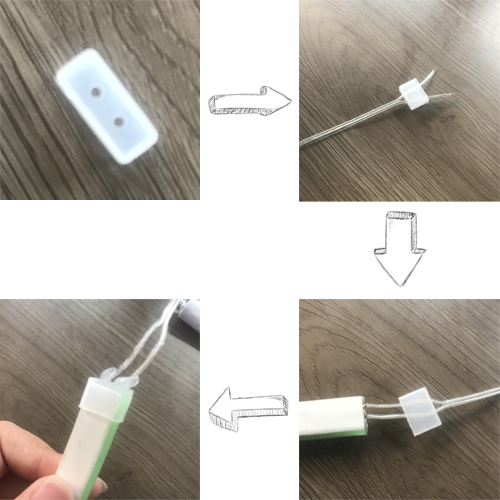

- First, pass the two transparent wires through the two holes of the square end cap. Pay attention to the cap’s direction—the open side must face the light strip. Please refer to the picture below.

- Then, connect the two wires to the positive and negative terminals of the light strip. Test the strip to ensure it lights up properly.

- Apply neutral waterproof silicone sealant evenly into this end cap. Again, fill about 1/3 to 1/4 of its volume.

- Finally, insert the wired end of the light strip into the cap. Press firmly until the sealant overflows around both the strip’s cover and the wire holes.

Step 4: Curing and Inspection

Let the assembly sit undisturbed until the sealant is completely cured. After curing, perform a water immersion or spray test to verify the waterproof result. Proceed with installation only after confirming there are no leaks.

Conclusion

By carefully selecting materials, matching the right end caps, and following proper installation steps, you can greatly improve the waterproof performance and service life of one-piece extruded neon lights in outdoor settings.

If you still encounter issues while waterproofing your one-piece advertising neon lights according to the steps above, please feel free to contact us. We are happy to discuss neon light solutions with you, even if you are not yet our customer.

Call to Action

As a professional manufacturer with 8 years of deep expertise in the neon lighting industry, One Zero LED Lighting Factory is committed to providing a full range of high-quality neon lighting products.

- Equipped with 6 specialized production lines and comprehensive in-house capabilities from R&D to manufacturing, we can flexibly meet the needs of diverse projects.

- Maintain substantial ready-to-ship inventory across our entire advertising neon light series, enabling fast dispatch within 3–7 days for small to medium orders. This ensures efficient support for urgent projects and allows your plans to proceed with confidence.

Let’s work together to illuminate spaces, ideas, and opportunities with professional products and service.

Contact us today to bring your vision to light.

Email Us: sales@onezeroledlighting.com

Call Us (Phone/WhatsAPP/WeChat): +86 18692631217